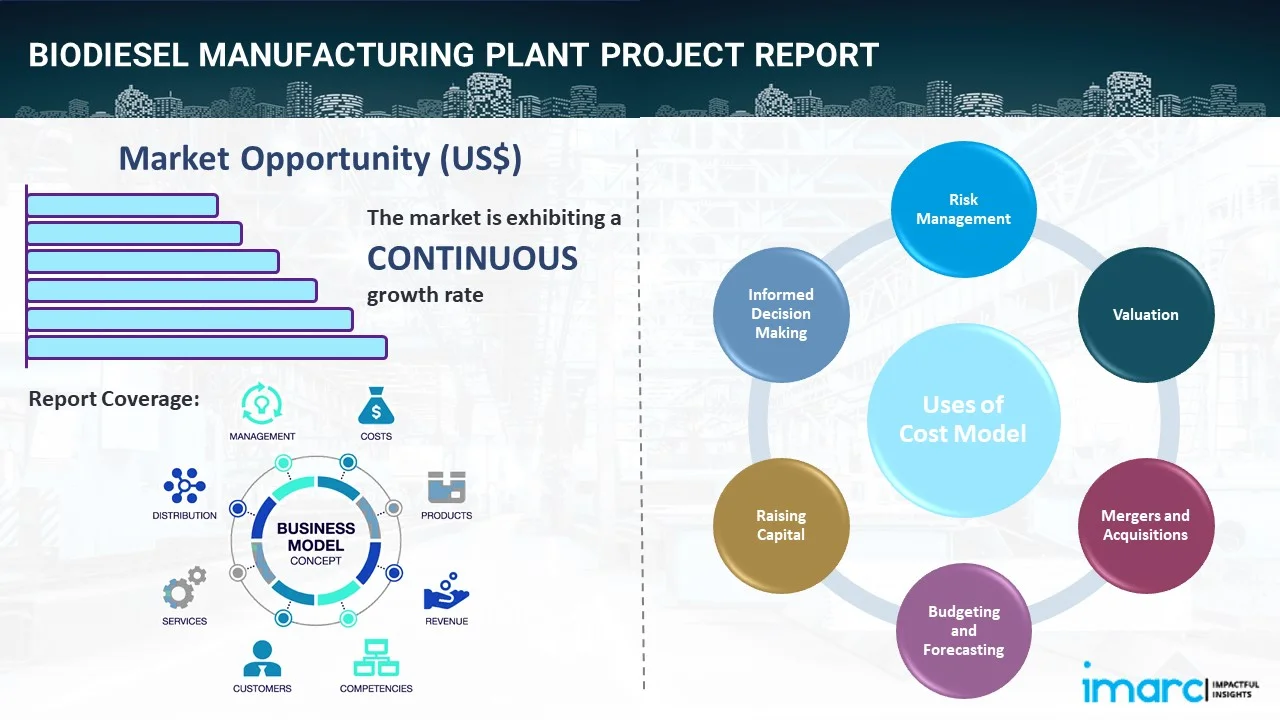

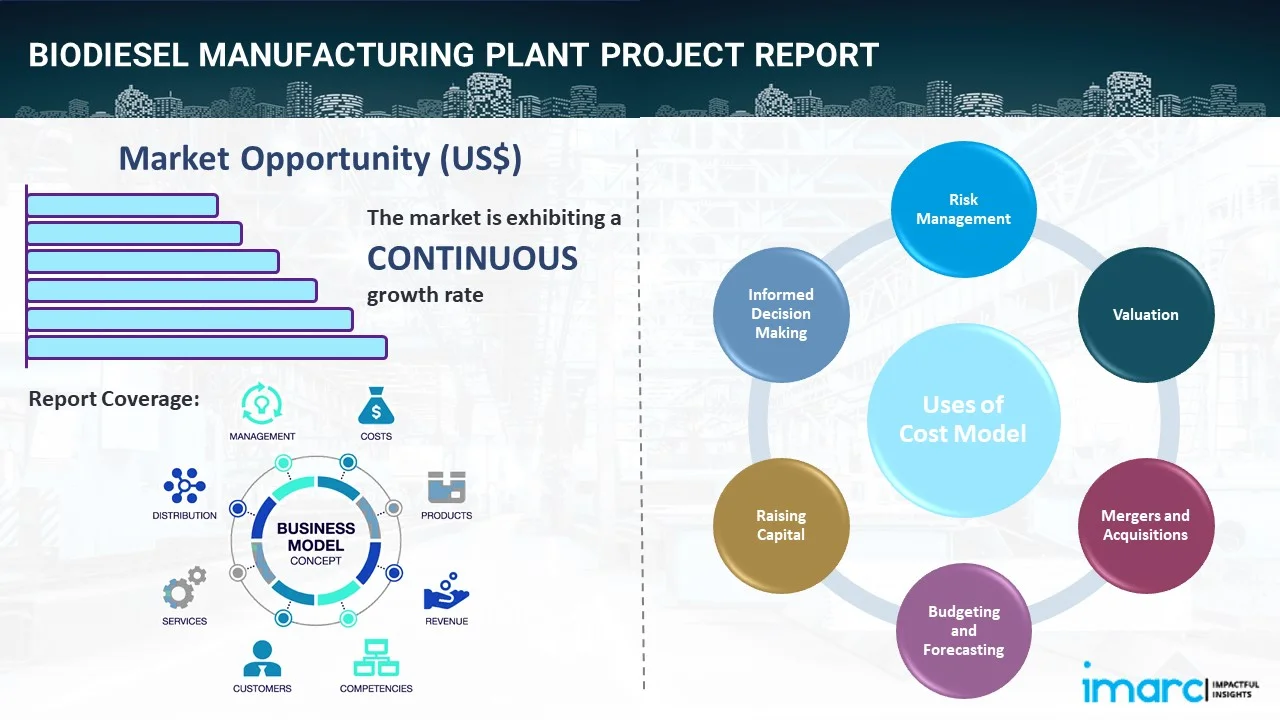

IMARC Group’s report, titled “Biodiesel Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a biodiesel manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The biodiesel project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

The biodiesel market is experiencing steady growth owing to the rising awareness of climate change and the need to reduce greenhouse gas (GHG) emissions driving the demand for biodiesel as a renewable alternative to conventional fossil fuels. Besides this, favorable government policies and regulations promoting renewable energy sources, along with incentives such as tax credits and subsidies, stimulate growth in the biodiesel market. For instance, the U.S. Environment Protection Agency (EPA), and the U.S. Department of Energy (DOE), introduced regulations to ensure that gasoline sold in the United States comprises a minimum volume of renewable fuel. The National Renewable Fuel Standard (RFS) program, also called the RFS Program, has set new registration, reporting, and compliance requirements for major refiners, fuel blenders, and fuel importers.

Government Policy Support

Government policies are shaping the market with subsidies, tax incentives, blending mandates, and sustainability regulations that influence production levels, investments, and market growth. The Energy Independence and Security Act of 2007 expanded and revised the Renewable Fuel Standard (RFS). Under the RFS Program, a mandatory mix of renewable fuel is integrated with transportation fuel, with the volume required increasing each year up to 36 billion gallons by 2022. The RFS program of renewable fuel categories must emit fewer greenhouse gases (GHG) than the gasoline or diesel they replace. Diesel should be produced from renewable feedstocks, such as biodiesel and non-ester renewable diesel that must illustrate the lifecycle greenhouse gas (GHG) emissions reduction of 50%. As per the U.S. Energy Information Administration (EIA), biodiesel is estimated for 9% of total U.S. biofuel consumption and production in 2022.

Sustainable Production Practices

The biodiesel industry has become committed to sustainable production practices. The Roundtable on Sustainable Biomaterials conference and other feedstock and products management initiatives are needed to ensure feedstock is sourced responsibly, encouraging responsible environmental management and corporate citizenship. Besides this, in January 2024, the U.S. Department of Energy (DOE) has granted a total of $118 million fund for 17 projects to reduce the carbon footprint of biofuel production by reaching commercial-scale for biofuel and bioproduct manufacturing. The projects, administered in universities and corporations, will advance commercial-scale biorefinery development, from pre-pilot to commercial, and lead to the domestic production of biofuels and bioproducts that are more environmentally friendly than using gasoline and diesel fuels. It further advances President Biden’s goals to advance an equitable, clean energy future, and to achieve a net-zero emission economy by 2050. The projects demonstrated through this funding opportunity will further meet DOE’s overall goal of producing cost-competitive biofuels and reducing greenhouse gas (GHG) emissions by at least 70% by 2030.

The market is also being driven by capacity expansions:

The following aspects have been covered in the biodiesel manufacturing plant report:

The report provides insights into the landscape of the biodiesel industry at the global level. The report also provides a segment-wise and region-wise breakup of the global biodiesel industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of biodiesel, along with the industry profit margins.

The report also provides detailed information related to the biodiesel manufacturing process flow and various unit operations involved in a manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, expenditure, and other biodiesel manufacturing plant costs. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

.webp)

The report also covers a detailed analysis of the project economics for setting up a biodiesel manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a biodiesel manufacturing plant.

Profitability Analysis:

| Particulars | Unit | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 |

|---|---|---|---|---|---|---|

| Total Income | US$ | XX | XX | XX | XX | XX |

| Total Expenditure | US$ | XX | XX | XX | XX | XX |

| Gross Profit | US$ | XX | XX | XX | XX | XX |

| Gross Margin | % | XX | XX | XX | XX | XX |

| Net Profit | US$ | XX | XX | XX | XX | XX |

| Net Margin | % | XX | XX | XX | XX | XX |

| Report Features | Details |

|---|---|

| Product Name | Biodiesel |

| Report Coverage | Detailed Process Flow: Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements |

Land, Location and Site Development: Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs

Plant Layout: Importance and Essentials, Layout, Factors Influencing Layout

Plant Machinery: Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request)

Raw Materials: Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request)

Packaging: Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request)

Other Requirements and Costs: Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs

Project Economics: Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation

Financial Analysis: Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis

While we have aimed to create an all-encompassing biodiesel plant project report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include: